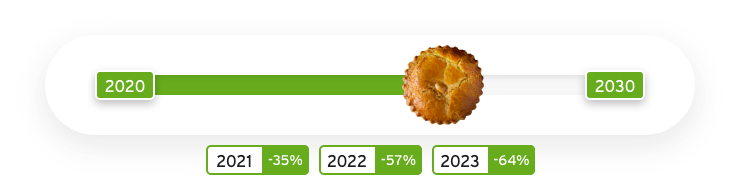

Our scope 1-2 footprint has been reduced by 64% since 2020.

We are proud to present the De Graaf Bakeries sustainability report for 2023, sharing the progress we have made in pursuit of our ongoing commitment to reducing our environmental impact and making our business practices more sustainable.

Our ambitions

We have translated the United Nations sustainable development goals into concrete objectives on which we as a company can make an impact. We focus on five priorities and take responsibility for each.

Climate consious

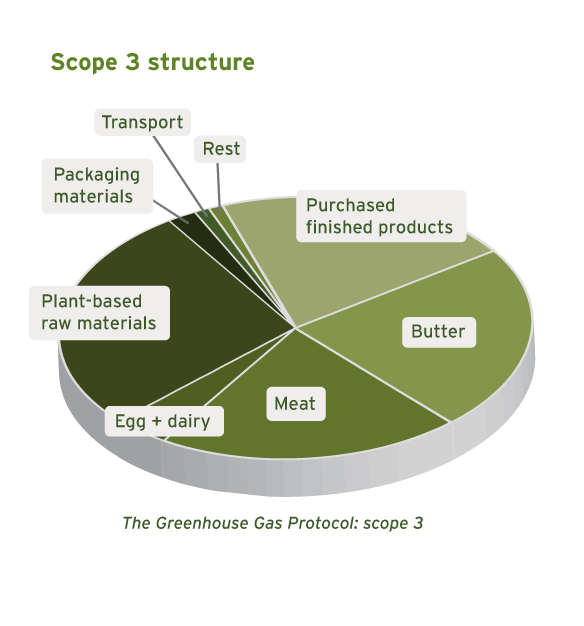

Achieve carbon neutrality by 2030 (scopes 1 and 2) and a 50 percent reduction in carbon emissions per kilogramme of product in scope 3.

Smarter packaging

100% recyclable packaging, with continuously decreasing environmental impact and maximum use of recycled materials.

Fair, short supply chain

Palm oil free, ‘Better Life’ meat, free-range eggs, and sourcing from within the Netherlands/European Union.

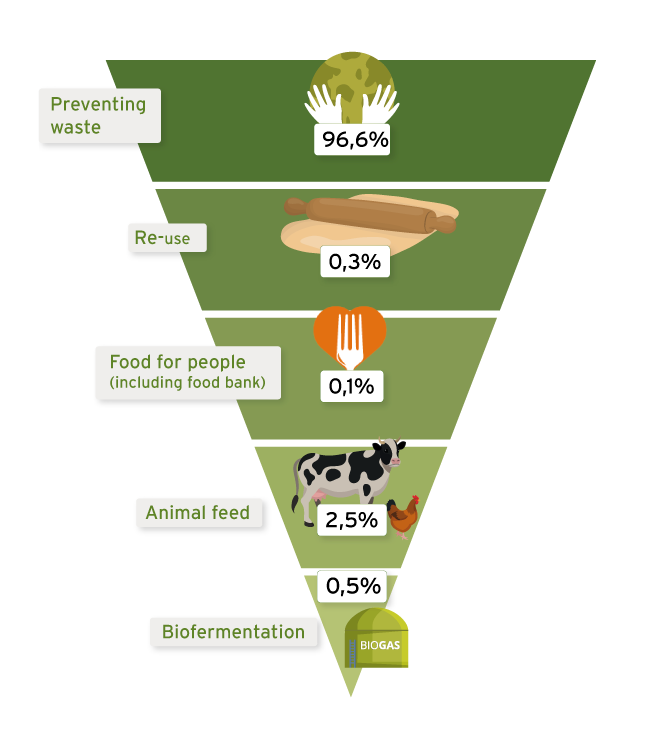

Less waste

< 1% product waste

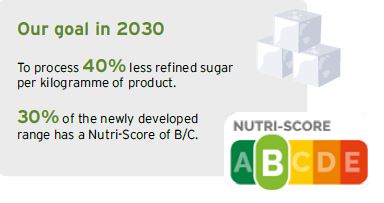

Healthier lifestyles

40% less refined sugar, with 30 percent of new products achieving a Nutri-Score of B or C.

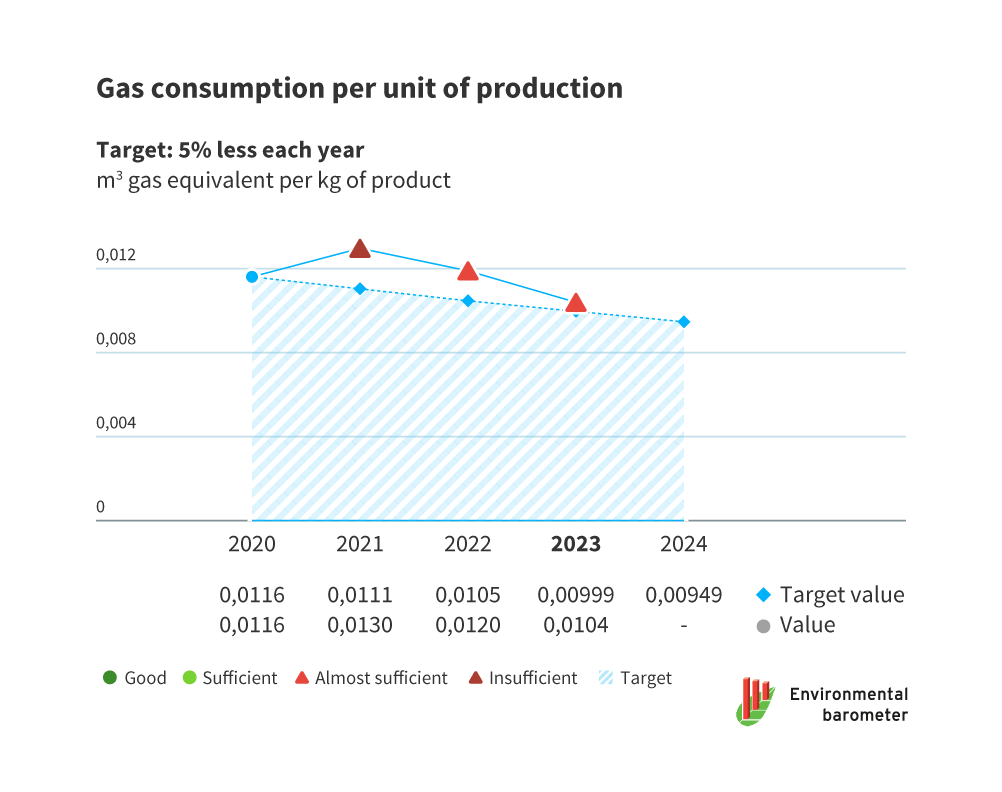

The Environmental Barometer displays our environmental impact

Since 2020, we have been filling out the Environmental Barometer to measure our environmental impact.

Our total impact in 2023 was a remarkable 32% less than in 2020, despite an increase in production volume of over 50% and the addition of the Emmen location since 2021.

Our impact per kilogramme of product has decreased by 55%.

At each production location, the environmental impact per kg of product has decreased:

In Hoogeveen, this reduction is 71% compared to our base year of 2020, primarily due to

- Emission reduction of CO2 gas through investment in the freezer tower to a closed cooling system in 2021

- Reduction of product and residual waste

- Optimization of freezer tower’s electricity consumption

In Spakenburg, there has been a 21% improvement compared to 2020, mainly due to

- More efficient use of gas ovens

- Less wastewater

- Reduced solid waste

- Reduced electricity consumption

In Emmen, our environmental impact in 2023 remained the same as in 2022, despite a 50% increase in production volume.

Our headquarters at Metaalweg in Spakenburg continues to consume less gas because since 2022, we have been heating it with waste heat from the adjacent freezer warehouse.

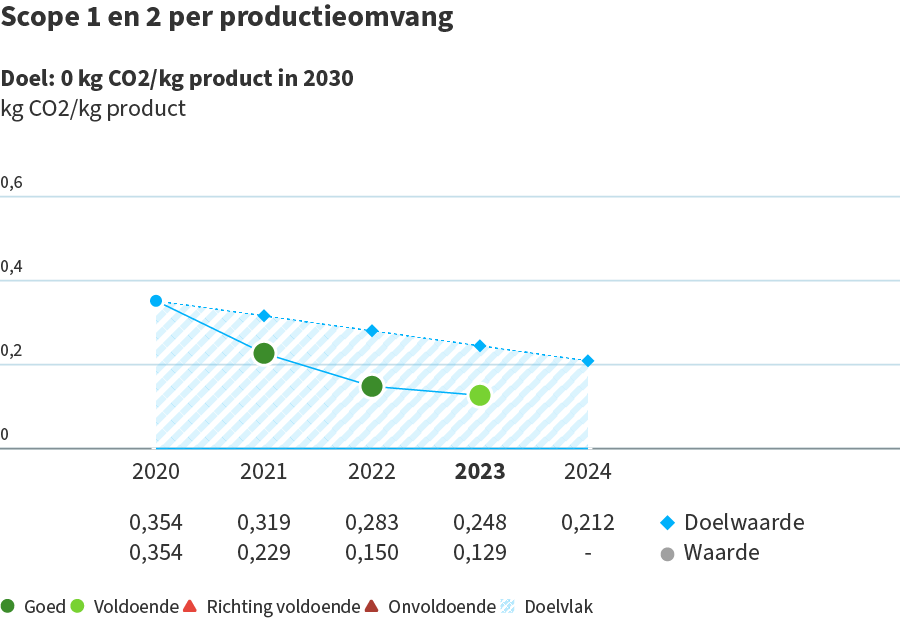

Our CO2 footprint

Climate Consious

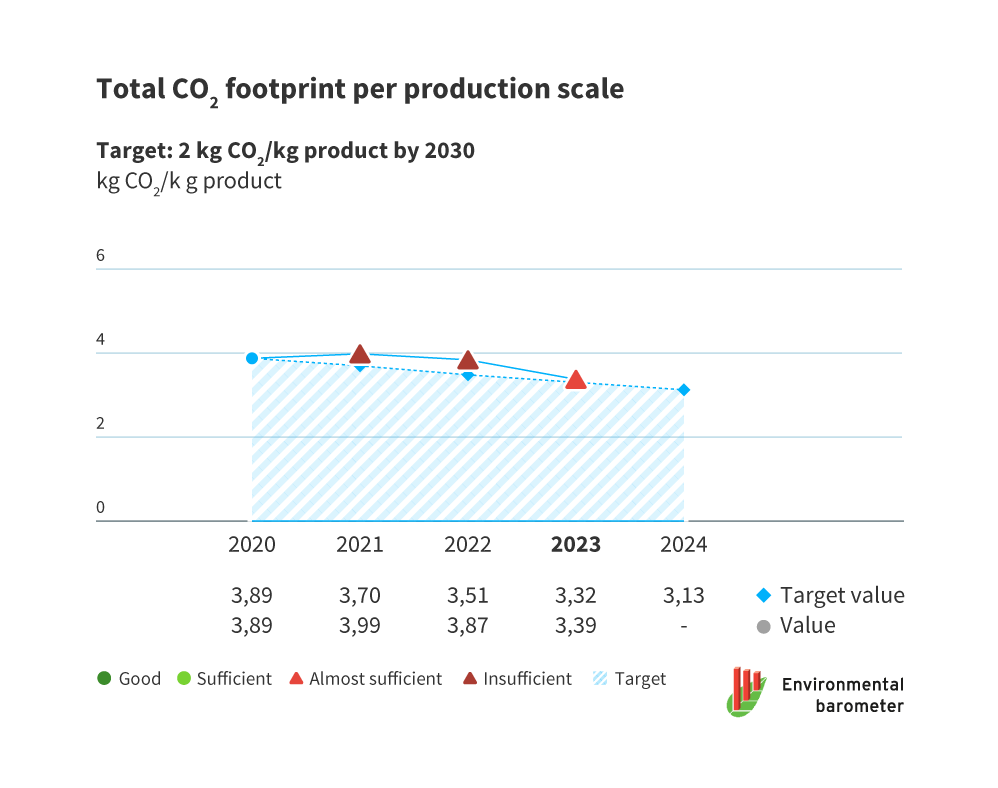

In 2023, we had our 2030 climate target for Scope 1 and 2 reviewed by SBTi and our near-term target was approved. This is our commitment to the Paris Agreement. Our efforts have resulted in a further 64% reduction in the Scope 1-2 Footprint per kg of product compared to our 2020 baseline, and a total reduction of 45% since 2020. To achieve our goal, we are committed to purchasing green electricity and electrifying our lease car fleet. In 2023, our total CO2 footprint per kg of product was 13% lower than in 2020, with an average carbon factor of 3.39 kg CO2 per kg of product.

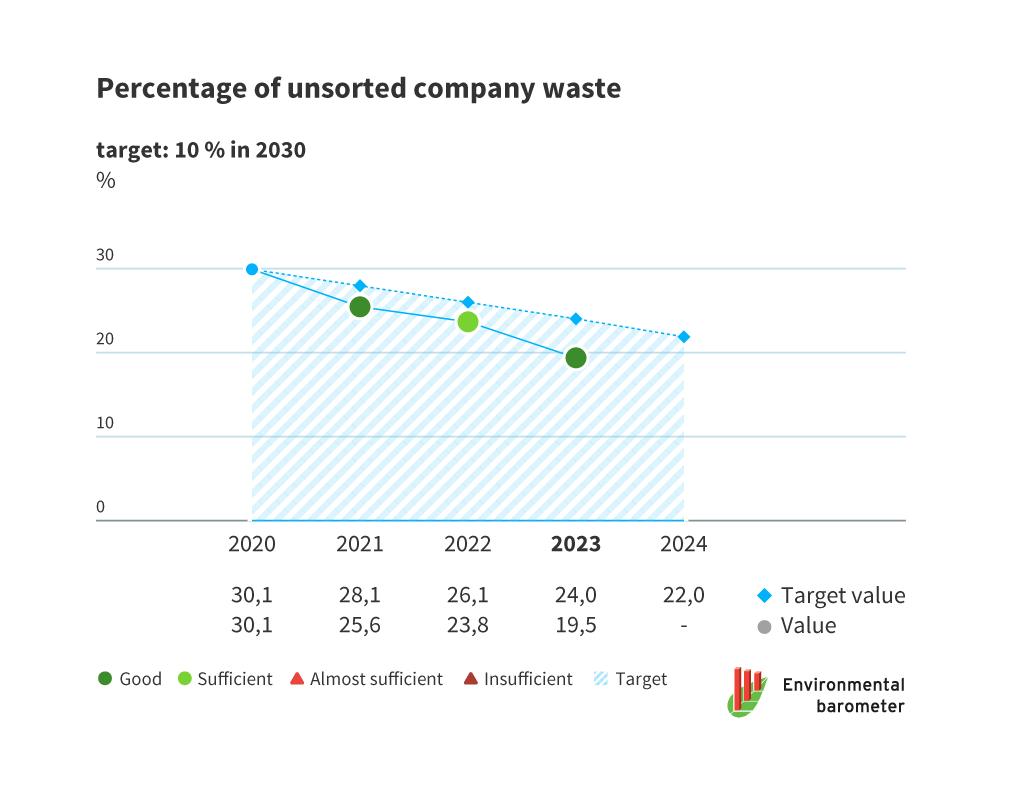

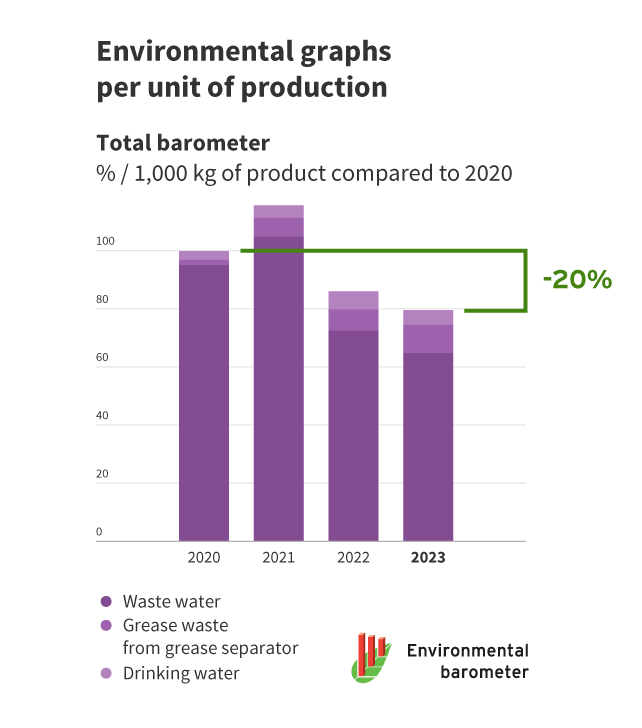

Less waste

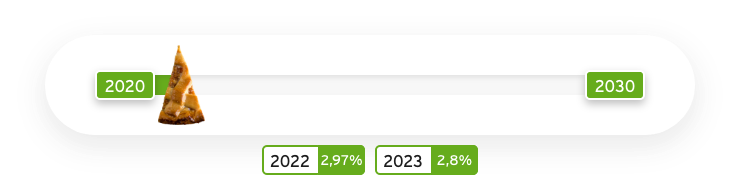

We aim to minimise food waste and maximise recycling. Our goal is less than 1% production waste by 2030. Last year, we reduced our production waste by 6%, particularly in Hoogeveen. In 2023, our total product waste, including logistics, reached 3.00%, while we reduced the residual waste stream from 30% to 20%. In 2023, we have also reduced the environmental impact of our waste and drinking water. We recovered 85% more product residues from cleaning water and used 9% less drinking water, reducing this category by 20% when compared to 2020.

Smarter packaging

Since 2023, we have accurate data regarding our packaging, which averages 81 grams per kg of product with an environmental impact of 87.5 grams of CO2. We are committed to 100% recyclable materials and reducing our environmental impact, with a focus on recycled materials. 99.3% of our packaging is now recyclable, with just 0.7% composite. All our cartons and trays are FSC® and/or PEFC® certified. In 2023, we have implemented a number of smarter packaging projects such as rationalising outer cartons, switching to paper clips to reduce waste and switching to brown cardboard.

Healthier Lifestyles

We offer healthier alternatives with less sugar, less fat and more fibre, including alternatives to all our bestsellers. We developed 12 products with a Nutri-Score of B/C in 2023. In 2024, our focus is on sugar reduction. The plan for this is already in place. In addition to product development, we are committed to providing fair, safe and healthy working conditions. This includes initiatives such as our internal Academy, employee satisfaction survey, ongoing risk inventory and assessments, investment in safety equipment, a health programme that includes fruit, a health bonus and a mobility scan that shows more cycling potential with a current B label.

Short, fair supply chain

Ecovadis awarded us a silver medal for sustainability in 2022. This audit will be repeated in 2024. We are working towards fully RSPO certified margarine and palm oil free alternatives. Our meat carries the Better Life label. Almost all our egg products are free range and 96% of our chocolate is Fairtrade or Rainforest Alliance certified. Our own brand products always carry the Better Life label for meat, eggs and Fairtrade chocolate. We focus on local sourcing of raw materials within the Netherlands and Europe. Our butter, flour, sugar, apples and raisins are 100% European.

Core values

What we believe in

Safety

- We work safely

- We ensure that everyone feels safe

- We adhere to the highest standards and regulations

Craftsmanship

- We make the tastiest quality products

- We are innovative

- We are professionals and strive for results

Customer oriented

- We prioritise quality and customer satisfaction

- We seek out new opportunities

- We collaborate, because you don’t become a market leader by going it alone

Team de Graaf

- We respect each other and are reliable

- We take the initiative and accept responsibility

- We have fun